- Membrane Hitec Team House, GST Road, Vandalur, Chennai 600 048, India.

- +91 44 2275 0323, 2275 0324, 6679 9595

Technology

Development of Ultrafiltration Membrane Technology

Membrane technology has assumed importance in the treatment of waste water and process streams. The immense potential of this technology has driven Dr Rao, a staunch environmentalist, to membrane technology largely due to its limited or absent use of chemicals, with the broad objective of "total elimination of conventional chemical process with eco-friendly and cost effective membrane separation technology by R3 process - Reduce, Recovery and Reuse".

Ultrafiltration is one of the membrane separation techniques which facilitates removal of suspended solids in liquid stream. Dr Rao's team in 1996 - 99, embarked on a quest to develop ultra-filtration hollow fibre membranes and selected Singapore to set up the research Centre, as the country that offers congenial atmosphere for the test-bedding of water treatment technologies. National Science and Technology Board, Singapore, recognising the merit and paramount importance of the research, readily bestowed a grant of two million Singapore dollars.

Dr Rao further demonstrated true commitment towards his research cause by independently investing 3 million Singapore dollars to set up Membrane Research Technology Singapore (MRTS), at the Alpha, Singapore Science Park II, a facility for test-bedding and commercialistion for water treatment technologies. MRTS successfully accomplished the deliverables and got the IPR registered in Singapore.

Establishment of Membrane Technologies Ltd - Now Membrane Hitec (MHT)

Successful research and accomplishment of deliverables by Membrane Research Technology Singapore (MRTS) - parent Company of Membrane Hitec, in Singapore, with the grant in aid from the National Science and Technology Board, Singapore, on "made in Singapore Ultra filtration membrane" was synergized with the establishment of its 100% owned – Membrane Technologies Ltd, in the year 1998, with repatriation benefits.

The Company, on a war-footing, rigged up the infrastructure and started the commercial production in March 1999. It also received good guidance and support from the eminent Global Membrane Scientists from Europe, USA, Australia and India.

UF Technology - Conventional Process

Conventional Water treatment uses combination of various treatment steps, mainly chemicals, to remove impurities. This avoids generation of sludge and prevents pollution.

The treated water quality fluctuates due to variations in feed water quality, often leading to instability in the downstream processing. Hence, the processing becomes inefficient.

- Purchase, transport and monitoring the addition of chemicals is complicated

- Requirement of a large floor area often with expensive civil constructions

- Scaling up capacity or expansion is complicated in the conventional systems

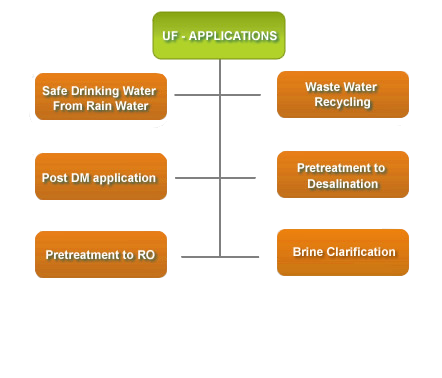

UF- Applications

UF - leading edge technology in water treatment process.

- Boiler Feed Water - Colloidal Silica Removal

- Pre-treatment to R/O - Reduction of SDI

- Drinking Water - Removal of Pathogens

- Pre-treatment to Desalination - SDI Reduction

- Cooling Tower - Removal of suspended Solids / Microbes

- Treated Sewage - TSS / Turbidity / SDI Reduction

- Process Effluent Recycling - TSS / Turbidity / SDI Reduction

- Brine Clarification - Chlor - Alkali - TSS / Turbidity Reduction

Advantages

Ultra-filtration offers several advantages over conventional methods:

- Low Operating Pressure (0.5 to 0.8 Bar)

- High Performance Anti Fouling Characteristics

- Operating in Dead End / Cross Flow

- MWCO Range 10 KD to 100 KD

- Same UF Feed Pump used for forward Flush A & B

- Elimination of pre-coat filters

- Lower Power Consumption

Powered By Copyright © 2010 : Membrane Hitec. All rights reserved

SEO Services : WEBDADS2U

Maintained by : Swathi Soft Solution